PowerFlex 525 Parameters Manual⁚ A Comprehensive Guide

This comprehensive guide serves as a valuable resource for understanding and utilizing the PowerFlex 525 drive’s parameters. Whether you are a seasoned engineer or a novice user, this manual will provide you with the knowledge and tools to effectively configure, operate, and troubleshoot your PowerFlex 525 drive. From basic setup to advanced parameter settings, this manual covers all aspects of the PowerFlex 525, empowering you to maximize its capabilities and achieve optimal performance in your motor control applications.

Introduction

The PowerFlex 525 is a versatile and powerful adjustable frequency AC drive designed for motor control applications. This manual provides a comprehensive guide to the parameters available within the PowerFlex 525, empowering users to configure and optimize the drive for diverse applications. The PowerFlex 525 features a modular design, making it easy to install and configure, while its embedded EtherNet/IP and PROFINET capabilities facilitate seamless integration with various industrial networks. The drive also incorporates a range of safety features, ensuring a secure operating environment for personnel and equipment. This manual delves into the various parameter groups available within the PowerFlex 525, explaining their functions and providing practical guidance on their usage. By understanding the different parameters and their impact on drive performance, users can fine-tune the PowerFlex 525 to meet the specific requirements of their applications.

This manual serves as a valuable resource for engineers, technicians, and operators involved in the installation, commissioning, operation, and maintenance of the PowerFlex 525 drive. It provides a detailed explanation of each parameter, along with its default value, range, and potential effects on the drive’s behavior. Users will find this manual to be a valuable companion in effectively configuring, troubleshooting, and maximizing the performance of their PowerFlex 525 drive.

This manual is a valuable resource for users of the PowerFlex 525 drive, serving as a comprehensive guide to the parameters available within the drive. It provides a detailed explanation of each parameter, along with its default value, range, and potential effects on the drive’s behavior. With this knowledge, users can confidently configure, optimize, and troubleshoot their PowerFlex 525 drive for optimal performance in various applications. The manual aims to empower users with the necessary information to effectively utilize the drive’s capabilities and achieve desired outcomes.

Key Features of the PowerFlex 525

The PowerFlex 525 drive is a robust and feature-rich solution for motor control applications, offering a range of functionalities designed to enhance performance, simplify configuration, and ensure reliable operation. Some of the key features that contribute to the PowerFlex 525’s versatility and user-friendliness include⁚

- Embedded EtherNet/IP: The PowerFlex 525 comes equipped with an embedded EtherNet/IP adapter, enabling seamless integration with industrial networks and facilitating communication with other devices on the network. This feature simplifies configuration and allows for easy access to drive parameters and diagnostics.

- USB Programming⁚ The drive supports USB programming, providing a convenient way to configure and update parameters, load applications, and access diagnostic information. This flexibility enhances user experience and simplifies maintenance tasks.

- Safety Features⁚ The PowerFlex 525 incorporates a range of safety features, including Safe Torque Off (STO), which ensures a safe operating environment for personnel and equipment. These safety features meet industry standards and regulations, contributing to workplace safety.

- PROFINET Option Card⁚ The drive offers a PROFINET option card, enabling integration with PROFINET networks and enhancing compatibility with various automation systems. This feature expands the drive’s applicability and facilitates communication with other PROFINET-enabled devices.

- Modular Design⁚ The PowerFlex 525 features a modular design, allowing for easy installation and configuration. The modularity simplifies maintenance and allows for customization based on specific application requirements. This approach contributes to the drive’s overall versatility and user-friendliness.

These key features make the PowerFlex 525 a versatile and reliable solution for a wide range of motor control applications, offering seamless integration, enhanced user experience, and robust safety features.

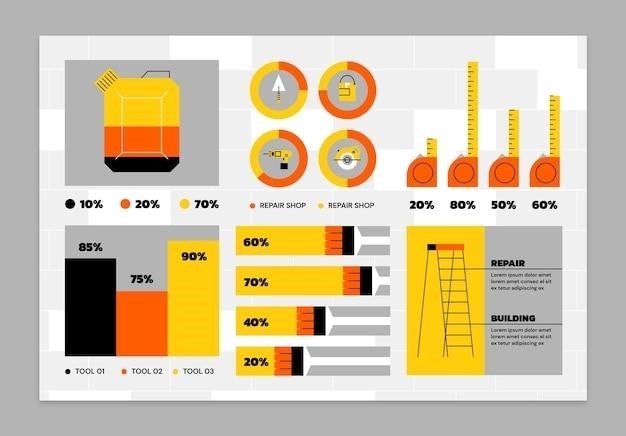

Parameter Groups and Their Functions

The PowerFlex 525 drive utilizes a structured parameter system, organized into distinct groups, to manage various aspects of its operation. Each parameter group encompasses a set of related settings, providing a logical framework for configuring and controlling the drive. Understanding the functions of these parameter groups is essential for effectively configuring and utilizing the PowerFlex 525.

- Drive Control Parameters⁚ This group defines fundamental drive parameters, including the motor type, motor rating, and operating modes. It allows you to set the basic configuration of the drive, aligning it with the connected motor and desired operation.

- Communication Parameters⁚ This group manages communication settings, including the network type, IP address, and communication protocols. It enables you to establish communication with the drive and integrate it into your network environment.

- Application Parameters⁚ This group houses parameters specific to your application, such as speed reference, acceleration, and deceleration settings. It allows you to tailor the drive’s behavior to your specific needs, ensuring optimal performance for your application.

- Safety Parameters⁚ This group contains settings related to safety features, such as Safe Torque Off (STO) and other safety functions. It allows you to configure and enable safety features, ensuring a safe operating environment for personnel and equipment.

- Diagnostic Parameters⁚ This group provides access to diagnostic information, including fault codes, operational data, and performance metrics. It helps you monitor the drive’s health and identify potential issues, facilitating troubleshooting and maintenance.

By understanding the functions of these parameter groups and their individual parameters, you can effectively configure and optimize the PowerFlex 525 for your specific motor control application, ensuring optimal performance and reliable operation.

Setting Up the PowerFlex 525 for Basic Operation

Getting your PowerFlex 525 drive up and running for basic operation involves a straightforward process, typically requiring minimal configuration. This initial setup aims to establish fundamental settings for the drive, enabling it to control the connected motor. The process typically involves configuring the motor parameters, defining the operating mode, and setting the speed reference.

- Motor Parameter Configuration⁚ The first step involves configuring the motor parameters. This includes specifying the motor type, its rated power, and other relevant characteristics. These parameters are crucial for the drive to accurately control the motor and ensure optimal performance.

- Operating Mode Selection⁚ Next, you need to select the desired operating mode for the drive. This could be a basic open-loop mode, where the drive operates based on a simple speed reference, or a closed-loop mode, which involves feedback from the motor to achieve precise speed control.

- Speed Reference Setting⁚ Finally, you need to define the speed reference for the drive. This could be a fixed value, a signal from an external source, or a value generated by a PLC or other control system. The speed reference determines the desired operating speed for the motor.

Once these basic settings are established, the PowerFlex 525 drive is ready to control the connected motor, enabling it to operate in accordance with the defined parameters. This basic setup provides a foundation for more advanced configurations and applications, allowing you to utilize the full capabilities of the PowerFlex 525.

Configuring Communication Protocols

The PowerFlex 525 drive offers versatile communication capabilities, allowing seamless integration with various industrial networks and control systems. Configuring these communication protocols is crucial for exchanging data, commands, and status information between the drive and other devices. The PowerFlex 525 supports a range of protocols, including EtherNet/IP, PROFINET, and RS-485, enabling flexible integration into diverse automation environments.

To configure the communication protocols, you typically use the drive’s built-in interface, which could be a web server, a dedicated programming software, or a combination of both. The configuration process usually involves selecting the desired protocol, setting the communication parameters like IP address, subnet mask, and gateway address, and defining the communication mode, such as client or server.

Once the communication protocol is configured, the drive can establish a connection with other devices on the network. This allows you to monitor the drive’s status, control its operation, and access its parameters remotely. The ability to communicate effectively with other devices enhances the flexibility, scalability, and overall efficiency of your automation system.

By leveraging the PowerFlex 525’s communication capabilities, you can seamlessly integrate it into your existing control infrastructure, enabling efficient data exchange, centralized control, and enhanced monitoring. This versatility makes the PowerFlex 525 a valuable asset for various industrial applications, ensuring smooth communication and streamlined operations within your automation environment.

Advanced Parameter Settings

Beyond the basic configuration, the PowerFlex 525 offers a comprehensive set of advanced parameters that enable fine-tuning of the drive’s performance and functionality. These parameters allow you to tailor the drive’s behavior to specific application requirements, optimizing its operation for various operating conditions and motor types.

Advanced parameters encompass a wide range of settings, including motor characteristics, control algorithms, protection features, and communication settings. For instance, you can adjust the drive’s acceleration and deceleration ramps to optimize motor starting and stopping, enabling smooth transitions and minimizing mechanical stress. You can also configure the drive’s current limiting settings to protect the motor and drive from overload conditions.

Furthermore, advanced parameters allow you to customize the drive’s response to different operating conditions, such as variations in load, temperature, or voltage. This ensures reliable operation and optimal performance even in challenging environments. By leveraging these parameters, you can achieve precise control, enhance efficiency, and extend the lifespan of both the drive and the motor.

The PowerFlex 525’s advanced parameter settings provide a powerful tool for optimizing drive performance and tailoring it to specific applications. By carefully configuring these parameters, you can maximize the drive’s capabilities, enhance efficiency, and ensure reliable operation in demanding industrial settings.

Troubleshooting Common Issues

While the PowerFlex 525 is a robust and reliable drive, occasional issues may arise. Understanding common troubleshooting techniques will help you quickly resolve these issues and minimize downtime. A systematic approach to troubleshooting is essential, starting with a thorough inspection of the drive and motor, followed by a review of the configuration parameters.

Common issues include communication errors, motor faults, and drive protection trips. Communication errors can be resolved by verifying network connections, checking for faulty cables, and ensuring proper configuration of communication parameters. Motor faults may indicate problems with the motor itself, such as winding issues or bearing failures. In such cases, inspecting the motor for signs of damage and performing necessary repairs or replacements is crucial.

Drive protection trips often occur due to overload, overcurrent, or overheating conditions. Reviewing the drive’s fault logs and examining the parameter settings related to protection levels can help identify the cause of the trip. Adjusting parameter settings, such as current limits or temperature thresholds, may be necessary to prevent future trips; In some cases, inspecting and cleaning the drive’s cooling system may be required to ensure proper heat dissipation.

By carefully analyzing the symptoms, reviewing fault logs, and utilizing the troubleshooting techniques outlined in the PowerFlex 525 user manual, you can effectively diagnose and resolve most common issues, ensuring smooth and reliable operation of your drive system.

Safety Features and Considerations

The PowerFlex 525 drive incorporates a comprehensive suite of safety features to protect personnel and equipment. These features are designed to minimize hazards and ensure a safe working environment. It is essential to understand and implement these safety features correctly to ensure optimal protection.

One key safety feature is Safe Torque Off (STO), which disables the motor’s torque output when activated. This function is crucial in applications where the motor needs to be quickly and safely stopped, such as during maintenance or emergency situations. STO can be implemented through dedicated safety inputs and outputs, providing a reliable means of preventing unintended motor movement.

In addition to STO, the PowerFlex 525 offers other safety functions, including overcurrent protection, overvoltage protection, and overtemperature protection. These functions monitor critical parameters and activate protective measures if thresholds are exceeded. For instance, overcurrent protection safeguards the drive and motor from excessive current draw, preventing damage or overheating. Similarly, overvoltage protection prevents damage to the drive’s electronics from excessive voltage levels.

It is imperative to follow all safety guidelines outlined in the PowerFlex 525 user manual and to consult with qualified professionals for proper installation, configuration, and operation of the drive. By implementing these safety features correctly and adhering to best practices, you can create a safe and reliable environment for your motor control applications.

PowerFlex 525 Application Examples

The PowerFlex 525 drive’s versatility and advanced features make it suitable for a wide range of industrial applications. From simple motor control to complex motion control systems, the PowerFlex 525 can be tailored to meet specific requirements. Here are a few examples⁚

In material handling applications, the PowerFlex 525 can be used to control conveyors, robots, and other automated systems. Its precise speed control and position feedback capabilities ensure efficient and reliable material movement. For example, it can be used to control the speed and position of a conveyor belt, ensuring accurate material delivery.

In packaging and processing industries, the PowerFlex 525 can be used to control packaging machines, filling lines, and other automated processes. Its ability to handle multiple motor control tasks and integrate with automation systems makes it a valuable asset in these demanding environments. For instance, it can be used to control the speed and position of a packaging machine, ensuring precise and efficient product packaging.

The PowerFlex 525 is also suitable for machine tool applications, where precise speed control and torque regulation are critical. It can be used to control CNC machines, milling machines, and other machine tools, providing smooth and accurate operation. For example, it can be used to control the speed and torque of a spindle motor in a CNC machine, ensuring accurate and efficient machining operations.

Using the PowerFlex 525 with RSLogix Studio 5000

RSLogix Studio 5000 is a powerful software environment from Rockwell Automation that enables you to configure, program, and monitor your PowerFlex 525 drive. It provides a comprehensive suite of tools for creating and managing drive applications, integrating them seamlessly with your automation system.

With RSLogix Studio 5000, you can access and modify the PowerFlex 525’s parameters, including speed control, torque control, and safety settings. You can also create custom logic programs to control the drive’s operation based on specific process requirements. The software provides a user-friendly interface for configuring communication protocols, such as EtherNet/IP and PROFINET, ensuring seamless data exchange between the drive and your automation system.

RSLogix Studio 5000 also allows you to monitor the drive’s performance in real-time, displaying key parameters like speed, torque, and status information. This real-time monitoring capability enables you to identify potential issues and troubleshoot problems quickly. The software also provides historical data logging capabilities, allowing you to analyze past performance and optimize your application.

By leveraging the capabilities of RSLogix Studio 5000, you can fully harness the power of the PowerFlex 525 drive, creating sophisticated and efficient automation solutions for your industrial applications.

PowerFlex 525 and PROFINET

The PowerFlex 525 drive supports PROFINET communication, a widely adopted industrial Ethernet protocol that enables seamless integration into automation systems. PROFINET offers a robust and reliable communication infrastructure for exchanging data between the drive and other devices on the network, such as PLCs, sensors, and other drives.

By utilizing PROFINET, you can achieve real-time data exchange, enabling precise control and monitoring of the PowerFlex 525 drive. PROFINET’s deterministic nature ensures consistent and predictable communication, crucial for applications requiring high levels of accuracy and responsiveness.

PROFINET also offers features like device diagnostics and fault reporting, allowing for quick troubleshooting and system optimization. This capability simplifies maintenance and ensures system uptime. The PowerFlex 525’s PROFINET support enables you to build flexible and scalable automation systems, easily integrating the drive into existing PROFINET networks or creating new networks tailored to your specific needs.

With its robust communication capabilities and integration with industry-standard protocols like PROFINET, the PowerFlex 525 drive offers a powerful and versatile solution for demanding industrial applications.